Some very basic fluid mechanics principles have been adapted to our case by our Pride Lab engineers. “When the water flow goes from a bigger section to a smaller section, the flow speed decreases and the pressure increases.” “Using this principle as an analogy to what happens below our boards (if water is coming from both side of the board), if the perimeter of the concave narrows, water will encounter resistance at the end of the concave creating a pressure which push up the board creating more lift. As a result, having a concave will add a greater sense of lift. Which also means more speed in smaller conditions." The Double Concave is coupled with the classic deep Hull channels.

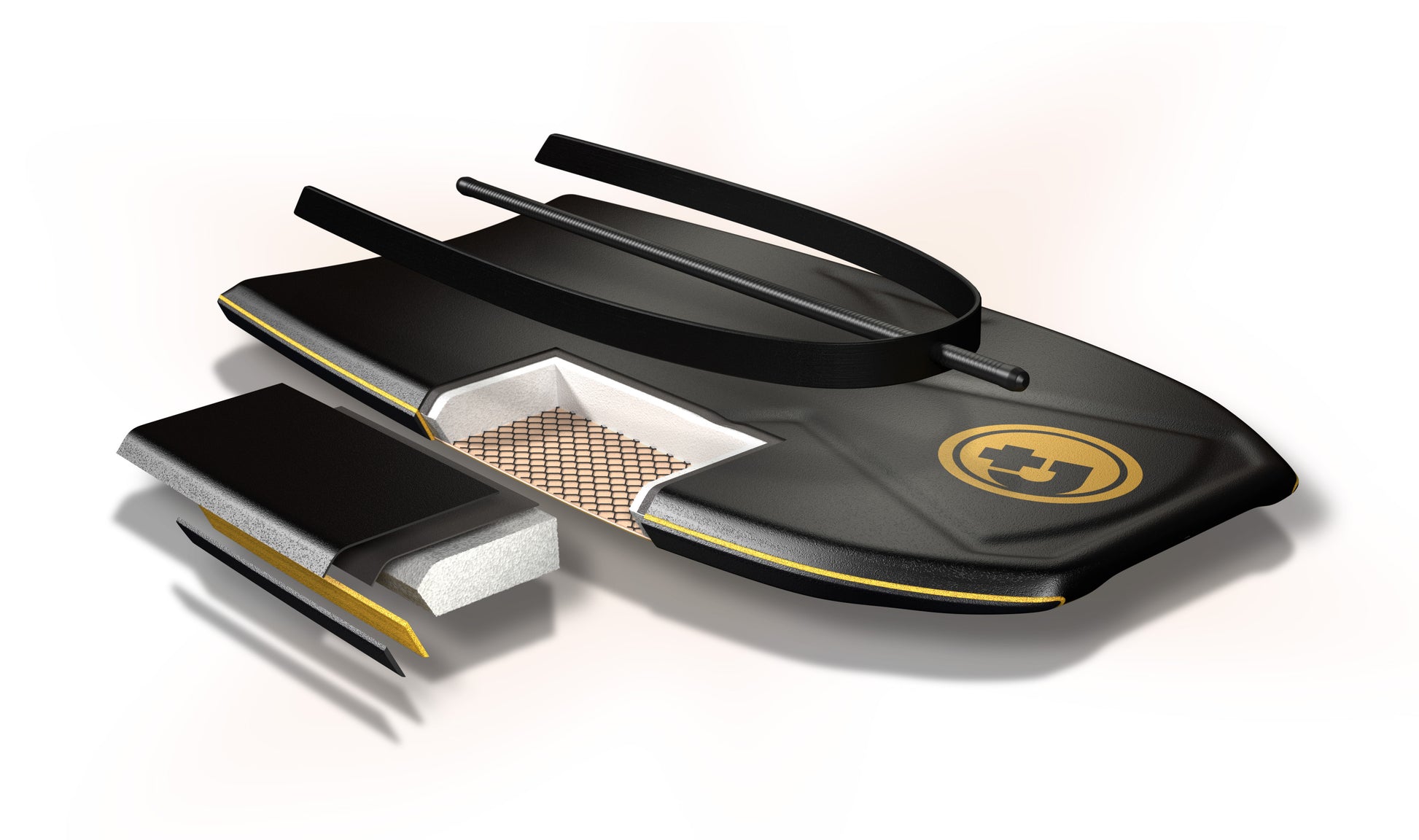

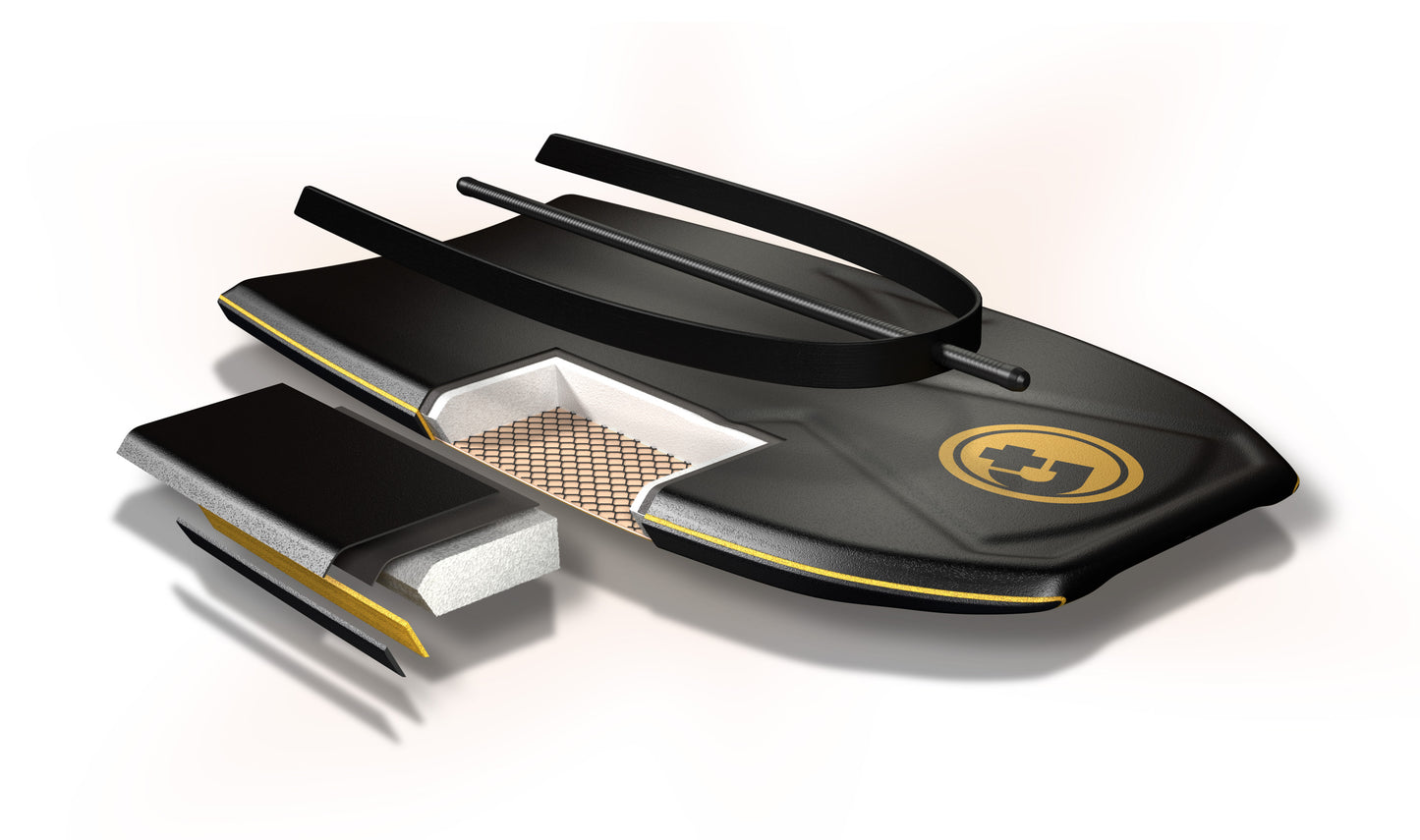

Radial Flex® was developed using the latest CAD software with integrated Generative Structural Analysis, allowing us to observe how a board reacts under typical wave riding load and flexion. The data showed us that when the rider pulls up on the nose of the board, the resulting structural load is directed through to the elbow in a radial pattern, and not in a direct line from hand to elbow.

Based on these findings we have developed the Dynamic Arc® technology. Constructed from a single beam of lightweight, high-tensile Divinycell structural foam, the Dynamic Arc® has been configured to disperse the structural load along its vertical surface.

By extending the natural curve of the Dynamic Arc® through to the tail of the board, we were also able to create a unique load-bearing frame that not only enables instant transfer from compression load to projection, but also distributes impact stresses, such as those caused by heavy landings, along the entire length of the frame.